Construction of Britain’s new high-speed railway has passed a major milestone with excavation of the 8.4-mile Northolt Tunnel under London. The fourth of four tunnel boring machines (TBMs) being used to dig the twin-bore tunnel - the second-longest on the HS2 route between London and the West Midlands - completed its work yesterday. The machine, named Anne, installed the final concrete ring underground before emerging into a vent shaft at Green Park Way in Greenford.

The Northolt Tunnel will take HS2’s new high-speed trains between West Ruislip at the outer edge of the capital and the new Old Oak Common super-hub station in west London.

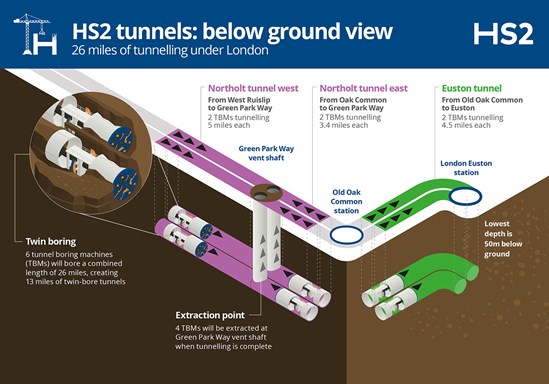

The Northolt Tunnel, which is 35 metres below ground at its deepest point, has been bored by HS2’s London tunnels contractor Skanska Costain STRABAG JV (SCS JV) using four TBMs. Two built the 5-mile western section from West Ruislip and two built the 3.4-mile eastern section from Victoria Road in North Acton.

TBM Anne, named after Lady Anne Byron, has now finished the second bore of the 3.4-mile eastern section completing the tunnel excavation.

All four machines finished their journey at Green Park Way where they are to be lifted out from the underground shaft. The third TBM, Emily, finished its tunnel bore earlier this month, and will be lifted out of the ground later this summer. The first two machines to arrive, from West Ruislip, were lifted out earlier this year.

In a complex engineering operation, high water pressure in the ground at the site at Green Park Way has meant that the TBMs are finishing their drives in steel reception cans installed in two underground shafts. The reception can method allows the TBM to maintain pressure while sealant can be applied from the tunnel lining, preventing water ingress. It is then depressurised before it is opened and the TBM is lifted out.

Northolt is one of five deep twin-bore tunnels on the 140-mile route and the second longest behind the Chiltern Tunnel, which is 10 miles long.

HS2 is currently undergoing a major reset led by Mark Wild, HS2 Ltd Chief Executive, to make sure the railway can be delivered to the lowest reasonable cost. While this work in ongoing, HS2 continues to make progress on major structures including tunnels and viaducts.

Alan Morris, Construction Delivery Director, HS2 Ltd, said:

“Completing the excavation of this 8.4 mile-long tunnel on HS2 is a real achievement and one the team should be immensely proud of.

“We’re building HS2 for the future, to increase capacity on our rail network and improve journeys for millions of rail users.

“The construction of HS2 is already bringing benefits, with £20bn economic benefit already being delivered at either end of the line.”

Lady Anne Byron was an educational reformer and philanthropist who lived between 1792 and 1860. She established the Ealing Grove School in 1834 – England’s first co-operative school which provided education for the working classes, in an era when it was mainly for the wealthy. The name was chosen by the local community around Ealing by a public vote.

TBM Anne was launched in April 2024 and has spent 14 months underground mining the tunnel. Three teams of 48 skilled workers have operated the giant machine around the clock to complete the work.

At peak, the 1,700 tonne TBM advanced at around 38 metres per day, with the crew ensuring the 9.11 metre diameter cutterhead cut through the earth, removed the clay, and then supported the excavated tunnel with concrete segments – each weighing up to 7 tonnes.

The excavated London clay is taken out of the tunnel using a conveyor system and, continuing on a horizontal conveyor system, is taken to HS2’s London Logistics Hub where it is then taken away by rail for beneficial reuse across the UK.

In total, the four machines, manufactured by Herrenknecht AG, have excavated 4,160,000 tonnes of London clay and lined the tunnel with 14,300 concrete tunnel rings, made up of 94,233 precision-designed concrete segments. The tunnel segments used by TBM Anne were made in Hartlepool by STRABAG and were transported to site by rail thereby minimising usage of London’s busy road network.

The inside width of the tunnel varies between the eastern and western section 8.10m in the east and 8.80m in the west. The tunnels for HS2 are wider for the sections of the route where the trains run faster given aerodynamic needs.

Richard Adam, Managing Director, SCS JV, said:

“The arrival of TBM Anne today marks a major milestone for both HS2 and SCS. This is the fourth and final TBM that completes the 8.4-miles twin-bore Northolt Tunnel. TBM Anne’s journey has been one of efficiency and precision, delivered safely and on schedule.

As we move forward, work continues at pace on the cross passages, tunnel fitout and surface structures and we are preparing to launch our final two TBMs to Euston early next year.”

Now the tunnel excavation is complete, the team will continue to build the flat tunnel invert on the base, creating a flat surface where high speed tracks will be laid. There will also be 34 cross passages mined between the two bores of the tunnel which the team continue to build.

The team are also completing five headhouses on the surface of the tunnel. The headhouses cover the ventilation shaft which connects the HS2 tunnel to the open air. It regulates air quality and temperature in the tunnel and allows smoke to be extracted in the event of a fire. The headhouse is the building on top of the ventilation shaft which contains fire control systems and the ventilation systems for the railway tunnels below.