HS2 today revealed the first of 68 giant piers that will support the high speed rail project’s first entirely off-site manufactured modular viaduct, in a move that represents a major step forward for viaduct design in the UK.

Unlike more traditional viaduct designs, every major element of the 880m long Thame Valley Viaduct will be manufactured in a factory before being slotted together on site like a giant Lego set, cutting its carbon footprint by around a third.

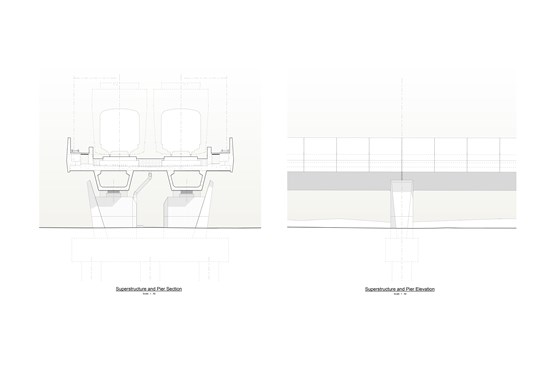

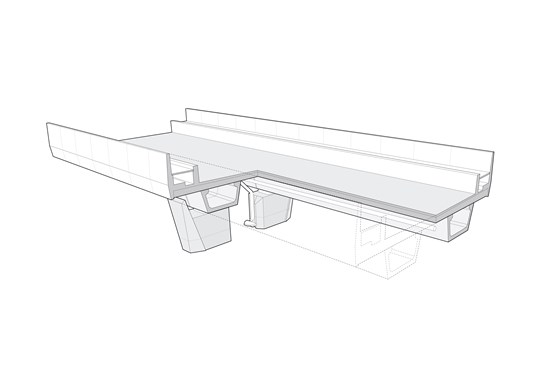

Applying lessons from the construction of recent high-speed rail projects in Spain, the design team opted for a simple structural solution with two 25m long hollow beams per span, which cuts the amount of carbon-intensive concrete and steel, while simplifying work on site.

These enormous 97 tonne beams – and the 42 tonnes piers that support them – are being manufactured at PACADAR UK’s factory on the Isle of Grain which also produces tunnel wall segments for HS2’s London tunnels. The workforce has doubled to 200 people who are employed at the factory delivering contracts for HS2, including apprentices and graduate engineers from nearby Universities.

Thame Valley is one of 15 viaducts designed by HS2 Ltd’s main works contractor, EKFB - a team made up of Eiffage, Kier, Ferrovial Construction and BAM Nuttall - working with on-site construction partner, FC Civils Solutions and pre-cast specialist, PACADAR UK, to build the innovative structure.

Welcoming the start of production, Tomas Garcia, HS2 Ltd’s Head of Civil Structures said:

“HS2 will offer zero carbon journeys from day one, providing a cleaner, greener way to travel and help the fight against climate change.

"But we’re also serious about cutting embedded carbon in construction, reducing cost and programme and improving safety, performance and durability. Thame Valley is a great example of how our contractors are embracing the latest engineering techniques to do just that. It’s great to see the start of work at PACADAR UK and I look forward to seeing assembly begin on site, later this year.”

Crossing the flood plain of the River Thame, just outside Aylesbury, the viaduct will carry HS2 trains at speeds of up to 360km/h between London, Birmingham and the North – dramatically improving journeys while freeing up space for more freight and local services on the existing network.

Set low into the landscape with a simple and consistent profile, the underside of the viaduct will be just 3m above the ground, with thirty-six even spans crossing the river and surrounding wetlands.

Traditionally, viaduct beams are secured together above each of the piers with a concrete diaphragm which is cast in situ. The larger pre-cast beams that will be used at Thame Valley can be secured directly to one another, removing the need for the diaphragm, improving durability and reliability, saving time, cutting cost and improving safety by reducing the need for people to work at height.

In another unusual move, the 68 concrete piers that support the viaduct will also be entirely made off-site before being placed on their foundations – meaning that every major element of the structure will be pre-fabricated.

As well as cutting embedded carbon in terms of materials, this approach requires less lorries to deliver material to site, simplifies construction, cuts waste and will reduce disruption for the community during construction.

Ignacio Chicharro, EKFB’s Project Director, said:

“This internationally inspired design is the product of best-in-class collaboration between HS2, EKFB and its design partners, Ferrovial Construction and FC Civils Solutions. The solution is a lightweight viaduct, set low into the landscape that benefits from the efficiencies associated with off-site prefabrication.

“Leaning on our on-site construction partner, FC Civils Solutions, to provide the expertise which comes with building a prefabricated structure, the viaduct will be slotted together piece by piece. Seeing the viaduct piers in production is a great milestone in the programme calendar and we’re excited to see the start of assembly on-site very soon.”

Fernando Aguilar Pírez, PACADAR UK’s Production Manager said:

“We’re delighted to have been awarded the contract to manufacture the precast concrete elements for the Thame Valley Viaduct. This solution is based on a modular design which is widely implemented by PACADAR on previous high speed lines. This contract reinforces our commitment to HS2 and we look forward to working on this project together with FC Civils Solutions and EKFB.

“PACADAR has brought state of the art construction method in order to optimize the use of materials, reduction of time and therefore remarkable savings and carbon footprint drop. Also using aesthetic solutions which minimize the visual impact on the environment.”